Soft Forming Servo Hydraulic Press

-

HPFS series Soft Forming Servo Hydraulic Press adopts full servo closed-loop control. The pressure, speed and stroke of the hydraulic machine can be set and saved on the touch screen. This equipment adopts PLC control, which is simple and convenient to operate.

Introduction

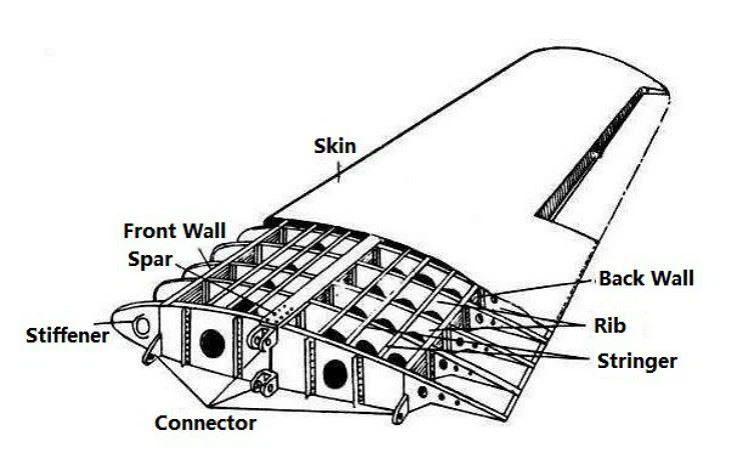

HPFS series Soft Forming Servo Hydraulic Press adopts full servo closed-loop control. The pressure, speed and stroke of the hydraulic machine can be set and saved on the touch screen. This equipment adopts PLC control, which is simple and convenient to operate. This series of servo forming hydraulic press is suitable for the production of small and medium skin parts for aircraft, soft forming of aluminum alloy sheet material. The special rubber upper mold of the equipment protects the workpiece surface from friction damage during the forming process. The material has no scratches on the surface after pressing, which is consistent with that before pressing to meet the high standards of the aviation industry for parts and components, the processed workpiece will not affect its physical properties. The equipment is equipped with automatic replacement rubber components, making replacement easy and quick. Mobile table support makes it easier to pick up parts.

The equipment is made strictly according to the export CE standard, which is a newly developed patented product of our company.

Technical Specifications

| No. | Soft Forming Servo Hydraulic Press | Unit | HPFS-500T | HPFS-1000T | ||

| 1 | Nominal Pressure | KN | 2500x2 | 3500x3 | ||

| 2 | Max. pressure of liquid | Mpa | 25 | 25 | ||

| 3 | Max. slider stroke | mm | 700 | 900 | ||

| 4 | Max. distance between the bottom of rubber and upper surface of movable worktable | mm | 600 | 650 | ||

| 5 | Nominal Force of Pushing Cylinder | KN | 25 x 6 pcs | 100 x 6 pcs | ||

| 6 | Stroke of Pushing Cylinder | mm | 700 | 400 | ||

| 7 | Worktable Size | F.B. | mm | 1200 | 2000 | |

| L.R. | mm | 1700 | 4000 | |||

| 8 | Movable Plate Size | F.B. | mm | 950 | 1200 | |

| L.R. | mm | 1500 | 3500 | |||

| Movable distance | mm | 1050 | 1550 | |||

| 9 | Material of movable plate | Cast Iron | Cast Iron | |||

| 10 | Rubber Size | F.B. | mm | 950 | 1200 | |

| L.R. | mm | 1500 | 3500 | |||

| 11 | Hardness of rubber | SHA | 75-80 | 75-80 | ||

| 12 | Thickness of rubber | Upper Layper | mm | 50(steel)+150 | 50(steel)+150 | |

| Middle Layer | mm | 150 | 150 | |||

| Lower Layer | mm | 200 | 200 | |||

| 13 | Slider Speed | Idle speed | mm/s | 120 | 120 | |

| Working | mm/s |

3-7.5

(The force can be 500T) |

3-7.5

(Force can be 1000T) |

|||

| Return | mm/s | 100 | 100 | |||

| 14 | Push Cylinder Speed | Down | mm/s | 50 | 35 | |

| Return | mm/s | 90 | 90 | |||

| 15 | Pulling Cylinder For Movable Plate Force | KN | 100 | 100 | ||

| 16 | Overall Dimensions | F.B. | mm | 2400 | 4400 | |

| L.R. | mm | 3100 | 5600 | |||

| Height above the floor | mm | / | 5865 | |||

| Total Height | mm | 5000 | 6265 | |||

| 18 | Servo Motor | KW | 29 | 56 | ||

| 19 | Servo Driver | KW | 30 | 75 | ||

| 20 | Voltage | 380V, 50Hz, 3 phase | ||||

| 21 | Quantity of locking cylinder to prevent slider from falling down | pcs | 2 | 2 | ||

| 22 | Operating Temperature | ℃ | 0-40 | |||

| 23 | Total Weight(Approx) | T | 27 | 116 | ||

Our Advantages

1. Complete production facilities: With a storage and processing center of 2000 square meters, it covers longitudinal cutting, horizontal cutting, laser cutting, drilling machine plasma grinder and embossing machine. Our technicians will regularly perform regular maintenance on these machines to ensure that they are working properly.

2.Exquisite production technology

We serve customers, achieve win-win" with high quality products and services.

Through unremitting efforts, we have provided hundreds of enterprises with hydraulic press, hydraulic press, four-column hydraulic press.

It has established long-term cooperative relations with Sany, Changchun FAW, Dongfeng Motor, power generation .

3.Perfect after sales service

Excellent servo numerical control hydraulic press and hydraulic press.

Import key brand products directly, Introduce of advanced experimental and testing instruments and equipment.

Services

1. Product quality control and delivery time is strictly controlled;

2. Direct manufacturing factory offering competitive price;

3. All the inquiries will be replied within 12 hours;

4. OEM & ODM service are available;

5. Providing first-class after-sales services to the customers.

FAQ

1.Q: What is your price level?

A: Factory direct sales

2.Q: How does your factory conduct quality control?

A: Two-year quality warranty and lifetime technical support.

3.Q: What kind of machinery can you produce?

A: The automobile industry, metal stretching. Single-column hydraulic presses, four-column hydraulic presses, frame hydraulic presses, servo hydraulic presses, etc. for various purposes such as plastic products and powder molding.

4. Q: Do you have stock?

A: Small tonnage machines will be in stock, but general products should be produced according to your order, including samples.

5.Q: What are your warranty terms?

A: We provide different warranty times for different products. Please contact us for detailed warranty terms.

Hot Tags: soft forming servo hydraulic press, China soft forming servo hydraulic press suppliers, manufacturers, factory, Aircraft Parts Press Machine, Servo Forming Hydraulic Press, Stretch Forming Machine, SMC Molding Machine, Sheet Stretch Forming Machine, Aluminum Chips Cleaning And Compacting Line