Auto Parts Hydraulic Press

-

The auto parts hydraulic press can be operated with automatic one cycle design; two hand push button design for simple and safe operation. Thefour column hydraulic presscould also realize three-operation mode: adjustment, manual and semi-automatic.

Introduction

The auto parts hydraulic press can be operated with automatic one cycle design; two hand push button design for simple and safe operation. Thefour column hydraulic presscould also realize three-operation mode: adjustment, manual and semi-automatic.

PLC press control is flexible and safe. Adjustable proximity switches allows stroke adjustments in seconds.

All our electrical, hydraulic and mechanical parts are standard in the industry and available throughout North America and Europe.The Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards;

Dual control you can select to use:

1.Moveable pedestal height for comfort and ease of operation c/w dual electric palm buttons & extra emergency stop;

2. Movable single-hand pedal switch.

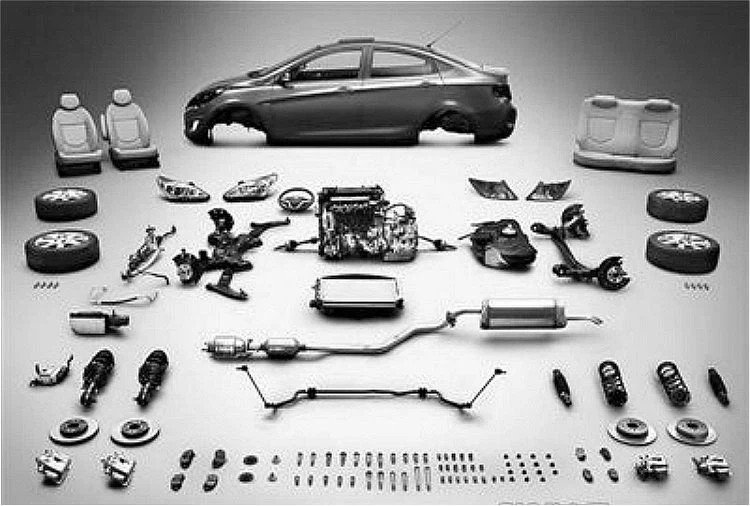

Application

Features

1. A new generation of numerical control hydraulic press, frame structure eight-sided guiding structure. Applicable technology, assembly, embossing, forming, punching, trimming.

2. Applicable to medium-sized parts in industries such as automobiles, motors, hardware, aviation, electronics, and electrical appliances.

3. The servo motor cooperates with the high-precision oil pump to drive the hydraulic cylinder.

4. PLC programming, touch screen display and control.

5. The displacement, speed, and pressure sensors are precisely controlled, and can be adjusted arbitrarily on the industrial touch screen.

6. Provide remote network service, and the machine will automatically alarm to indicate failure and maintenance.

Our service and Advantages

1.We have many experience on OEM work.

2.We can customize special hardware as customer demand.

3.Technical service for assembling.

4.Variety types for selection, prompt deliver.

5.Well-equipped with extensive sales network.

6.Advanced Production equipment and production technique.

7.Competitive Price (Factory direct price) with our good service.

8.Different designs are available according to customer requests.

9.Excellent quality testing equipment, 100% inspection on critical .

Production Process

1.Raw Material

2.Whole Plate Grinding

3.Blanking

4.Welding

5.Fine Finishing

6.Polish

7.Upper Primer

8.Assemble

9.Spray Paint

10.Finished

FAQ

1.Q: Can I know which payment your company accepts?

A: So far, we can provide 100% T/T before shipment, and 30% deposit paid by T/T, and the balance paid by L/C.

2. Q: How to obtain after-sales service?

A: The two-year warranty is free. If there is any problem, our technicians will communicate via phone or video. If necessary, we will come to the scene to solve the problem for you or replace the goods for you.

3. Q: How can I trust your company?

A: With ten years of professional design, we can provide you with suitable suggestions and lowest prices

1. All products have passed the third party evaluation ISO evaluation.

2. For our machines, we have done a good job on the equipment.

Hot Tags: auto parts hydraulic press, China auto parts hydraulic press suppliers, manufacturers, factory, Wheel Cover Press Forming Machine, Auto Parts Hydraulic Press, Auto Trim Hydraulic Press, Hydraulic Press For Car Body Parts, Car Body Making Machine, Car Body Press