Stretch Forming Machine

-

The Stretch Forming Machine adopts full hydraulic servo closed-loop control, which is easy to operate and has high production efficiency.

Introduction

The Stretch Forming Machine adopts full hydraulic servo closed-loop control, which is easy to operate and has high production efficiency. It is mainly used in a variety of industries, such as aircraft keel brackets, building circular steel structures, bridge engineering, motor vehicles, roof curved beams, subway engineering, curtain walls, cylindrical inner frames, production line tracks, display racks and other industries.

After the equipment’s stretch forming, the workpiece is perfectly curved, will not damage the surface of the workpiece, has high accuracy, good stability, and is not easy to deform. Hollow, complex cross-section profiles can be formed at one time. When the relative bending radius allows, the inner wall will not wrinkle and the cross-section will not be distorted (according to the drawing and bending process operation, using auxiliary materials to fill and stretch forming).

Specifications

| NO. | Item | Unit | HPCP-120Tx9m | HPCP-120Tx12m | HPCP-160Tx16m | |

| 1 | Single Arm Max.Tension | Tons | 120 | 120 | 160 | |

| 2 | Length of Single Arm | mm | 5520 | 7450 | 9200 | |

| 3 | Max. Length Stretch Forming | mm | 9000 | 12000 | 16000 | |

| 4 | Min. Length Stretch Forming | mm | 1800 | 2000 | 2500 | |

| 5 | Min. Stretch Forming Radius | mm | 800 | 1000 | 1000 | |

| 6 | Max. Stretch Forming Radian | ° | 180 (Semicircle) | 180 (Semicircle) | 180 (Semicircle) | |

| 7 | Jaws | Max.Clamping Section | mm | 350 x 350 | To be determined | 300 x 300 |

| Height from jaws axis to top of stretch table | mm | 260 | To be determined | 250 | ||

| 8 | Manual Rotation of Jaw | Clockwise | ° | 30 | 30 | 30 |

| Counterclockwise | ° | 30 | 30 | 30 | ||

| 9 | Table Dimensions(Length X width X height) | mm | 2400 X 2010 X 1105 | 3000 X 2200 X 45 | To be determined | |

| 10 | Clamping Cylinder | Quantity | pcs | 2 | 2 | 2 |

| Nominal Force | Tons | 25 | 25 | 30 | ||

| Bore Diameter | mm | 150 | 150 | 150 | ||

| Rod Diameter | mm | 90 | 90 | 90 | ||

| Jaw Design Type | Conical | Round | Standard design | |||

| Stroke | mm | 80 | 80 | 80 | ||

| 10 | Tensile Cylinder | Quantity | pcs | 2 | 2 | 2 |

| Nominal Force | Tons | 120 | 120 | 160 | ||

| Bore Diameter | mm | 320 | 320 | 350 | ||

| Rod Diameter | mm | 180 | 180 | 160 | ||

| Stroke | mm | 1100 | 1100 | 1100 | ||

| Tensile speed | m/min | 4.5 | Adjustable | 1 | ||

| 11 | Stretch Bending Cylinder | Quantity | pcs | 2 | 2 | 2 |

| Nominal Force | Tons | 120 | 120 | 160 | ||

| Bore Diameter | mm | 280 | 280 | 320 | ||

| Rod Diameter | mm | 120 | 120 | 120 | ||

| Stroke | mm | 1800 | 2000 | |||

| Positioning Accuracy | mm | ±0.5 | ±0.5 | ±0.5 | ||

| Stretching Speed | mm/min | 0-5400 (Adjustable) | (Adjustable) | 0-1500 (Adjustable) | ||

| 12 | Middle Push Ejector for profile | Quantity | pcs | / | / | 1 |

| Nominal Force | Tons | / | / | 100 | ||

| Stroke | mm | / | / | To be determined | ||

| 13 | Motor | Brand | Siemens | PHASE | Siemens | |

| Quantity | pcs | 2 | 2 | 2 | ||

| Power | KW | 18.5+22 | 28.7+28.7 | 37+37 | ||

| 14 | Pump | Brand | Sunny | Sunny | Sunny | |

| Quantity | pcs | 2 | 2 | 2 | ||

| 15 | Hydraulic System | Quantity | set | 1 | 1 | 1 |

| Quantity | Hangzhou Deke, China | Hangzhou Deke, China | Hangzhou Deke, China | |||

| Control Proportional | % | 0-100 | 0-100 | 0-100 | ||

| Oil Tank Volume | Liters | 1050 | 1050 | 1800 | ||

| 16 | Hydraulic Valve Group | Rexroth, Germany | Rexroth, Germany | Rexroth, Germany | ||

| 17 | PLC | Siemens, Germany | AB, USA | Siemens, Germany | ||

| 18 | Touch Screen | Siemens, Germany | AB, USA | Siemens, Germany | ||

| 19 | Main Electrical Components | Schneider, France | Schneider, France | Schneider, France | ||

| 20 | Remote Control Device | Brand | China Brand | |||

| Application | Wireless remote control can control the tensile, bending, clamping cylinder. | |||||

| 21 | Pull Line Sensor | Brand | NOVO, Germany | VOLFA, Germany Brand | Volfa, Germany | |

| Quantity | pcs | 4 | 4 | 5 | ||

| 22 | Voltage | 380V, 50Hz, 3Phase | ||||

| 23 | Host Area | mm | 15000 x 8000 | 18000 x 10000 | To be determined | |

| 24 | Equipment power supply required | KW/H | 40.5 | 57.4 | 74 | |

| 25 | Equipment dimensions | mm | 6500 X 2400 X 1105 | 8100 X 2500 X 1850 | To be determined | |

| 26 | Hydraulic Station Dimensions | mm | 1600 X 1200 X 1150 | To be determined | 1800 X 1400 X 1250 | |

| 27 | Control Cabinet Dimension | mm | 700 X 430 X 1300 | To be determined | To be determined | |

| 28 | Equipment weight | Tons | 26 | To be determined | To be determined | |

| 29 | Color | RAL5010 | ||||

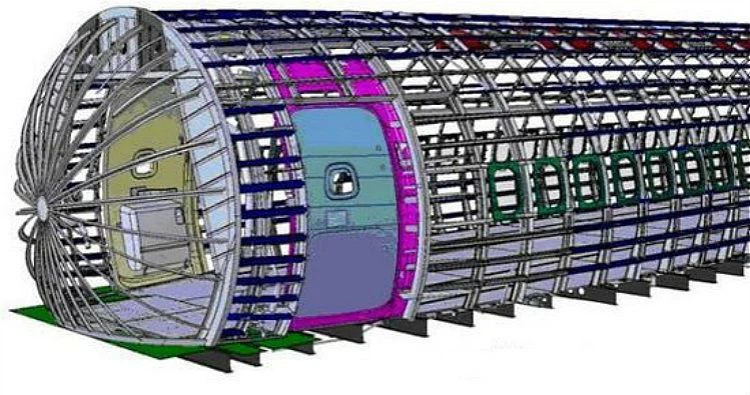

Pictures of stretch forming machine (Pictures just for reference only.)

HPCP-120Tx9m

HPCP-160Tx16m

FAQ

Q1: How can I get a quotation?

A1: Pls tell us the machine you need, including quantity, raw materials and other requirements.

Q2: After I buy the machine, what will you do if I don't know some of the function?

A2: We will show you how to use the machine perfectly. Technical support and the video is available.

Hot Tags: stretch forming machine, China stretch forming machine suppliers, manufacturers, factory, Soft Forming Servo Hydraulic Press, Hot Forming Hydraulic Press, Servo Forming Hydraulic Press, SMC Molding Machine, Aluminum Chips Cleaning And Compacting Line, Aircraft Parts Press Machine