PVC Hot Material Forming Machine

-

Introduction YD71 series PVC material molding machine adopts full CNC servo control. During the molding of PVC products, the molding machine can set the pressure value, speed, position, pressure holding time, mold opening speed, etc. arbitrarily. Molding process The PVC raw material is laid flat…

Introduction

YD71 series PVC material molding machine adopts full CNC servo control. During the molding of PVC products, the molding machine can set the pressure value, speed, position, pressure holding time, mold opening speed, etc. arbitrarily.

Molding process

The PVC raw material is laid flat on the lower mold by heating and extruding the hot material, and after the upper and lower molds are tightly sealed, the delay pressure is carried out. The temperature of the mold can be precisely controlled by a chiller, and the preheated material is solidified after a period of high pressure on a special PVC forming hydraulic press, and the finished product is removed from the mold, and the product is completed after trimming the flash. This molding process has the advantages of high strength, high precision, light weight, less impact on the environment, and is conducive to mass production, and is suitable for mass production of standardized parts.

Features

Precisely control the pressure value

Precise control of speed and position

Edit at will, save the program corresponding to the product number

Precise control of hot plate temperature

Efficient deodorization and purification system

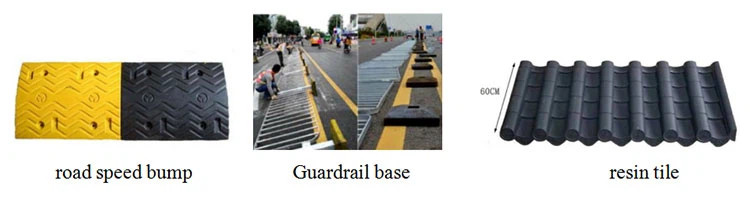

Applicable products and industries: (transportation)

|

Description |

Unit |

100T |

200T |

315T |

500T |

630T |

1000T |

1500T |

2000T |

|

|

Nominal Force |

KN |

1000 |

2000 |

3150 |

5000 |

6300 |

10000 |

15000 |

20000 |

|

|

Pressure of fluid |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

|

Slider stroke |

mm |

600 |

800 |

800 |

1200 |

1200 |

1600 |

1600 |

2000 |

|

|

Opening height |

mm |

900 |

1200 |

1200 |

1600 |

1600 |

2000 |

2000 |

2500 |

|

|

Ejecting stroke |

mm |

150 |

170 |

180 |

180 |

180 |

200 |

220 |

250 |

|

|

Preload pressure |

KN |

315 |

630 |

1000 |

1500 |

2000 |

3150 |

5000 |

6300 |

|

|

Opening Mould Force |

mm/s |

200 |

400 |

630 |

1000 |

1250 |

2000 |

3150 |

4000 |

|

|

Demould Force |

mm/s |

100 |

200 |

500 |

500 |

500 |

500 |

500 |

500 |

|

|

Down Speed |

mm/s |

200 |

200 |

200 |

200 |

200 |

300 |

300 |

300 |

|

|

Working speed |

mm/s |

1—6 |

1—6 |

1—6 |

1—6 |

1—6 |

0.5—5 |

0.5—5 |

0.5—5 |

|

|

Return Speed |

mm/s |

100 |

100 |

100 |

150 |

150 |

200 |

200 |

200 |

|

|

Preload Speed |

mm/s |

2—25 |

2—25 |

2—25 |

2—25 |

2—25 |

2—25 |

2—25 |

2—25 |

|

|

Demould Speed |

mm/s |

5—30 |

5—30 |

5—30 |

5—30 |

5—30 |

5—30 |

5—30 |

5—30 |

|

|

Table Size |

L.R. |

mm |

630 |

900 |

1200 |

1400 |

1600 |

3200 |

3200 |

3600 |

|

F.B. |

mm |

630 |

900 |

1200 |

1400 |

1600 |

2200 |

2200 |

2500 |

|

|

Master Pump Power |

KW |

11 |

18.5 |

30 |

45 |

75 |

110 |

180 |

230 |

|

|

Weight |

T |

4.2 |

12 |

22.5 |

43.5 |

56 |

112 |

162 |

222 |

|

Our Company

Kelai is a professional CNC servo press manufacturer integrating R&D, production and sales. Mainly engaged in more than 100 varieties of single-column, four-column, and frame-type servo hydraulic presses.

Kelai hydraulic press machines are suitable for drawing,bending,flanging,cold extruding,blanking processes for metal materials;straightening,press-in and forming processes for powder and abrasive products,plastic and insulation materials.