Seal Head Forming Production Line

-

Introduction There are many types of heads, which can be divided into oval head, butterfly head, spherical crown head, hemispherical head, bow head, flat bottom head, conical head and so on according to the shape. The head production line realizes the full automation of feeding, centering,…

Introduction

There are many types of heads, which can be divided into oval head, butterfly head, spherical crown head, hemispherical head, bow head, flat bottom head, conical head and so on according to the shape.

The head production line realizes the full automation of feeding, centering, oiling, pressing and discharging of the head in the pressing process, which greatly improves the processing efficiency and quality of the head and reduces the labor intensity of the workers.

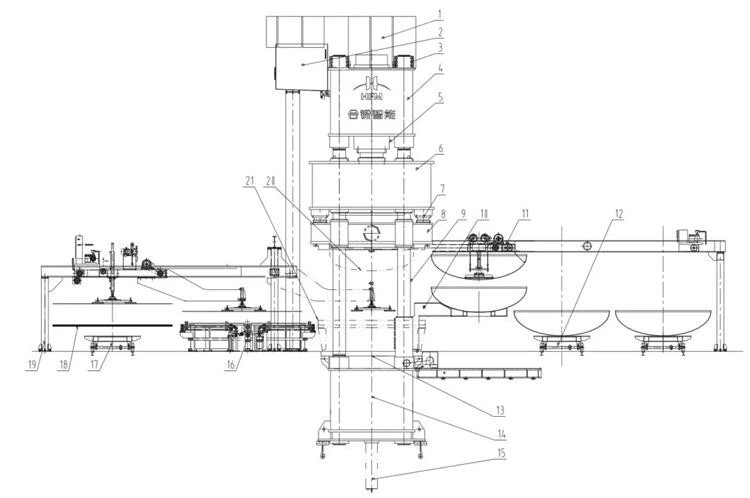

Head deep drawing hydraulic press is suitable for cold pressing and bending of metal sheets, deep drawing and other processes. It is a special equipment for producing large heads, drawing cylinders and large metal containers. The head forming part is shown in Figure 1.

Image 1 Head forming parts

The overall structure of the production line

The outline drawing of the head stretching hydraulic press and production line is shown in Figure 2. The body of the head stretching hydraulic press adopts a four-column or frame structure. Generally, the head stretching hydraulic press of the formed parts adopts a four-column type with a simple structure and is guided by the four-column. The head piece with high precision requirements adopts a frame structure and is guided by four-corner and eight-sided plane guide rails, with high guiding precision and strong anti-eccentric load capacity.

Image 2 Outline drawing of head stretching hydraulic press

1-protection device 2-main oil tank 3-nut 4-upper beam 5-stretching cylinder 6-stretching slider 7-side pressing cylinder 8-side-holding slider 9-upright column 10-rotating device 11-cutting device 12 - Discharging trolley 13 - Moving table 14 - Lower beam 15 - Ejector rotating device 16 - Centering device 17 - Feeding trolley 18 - Blank 19 - Loading device 20 - Drawing die 21 - Lower die

Head stretching process

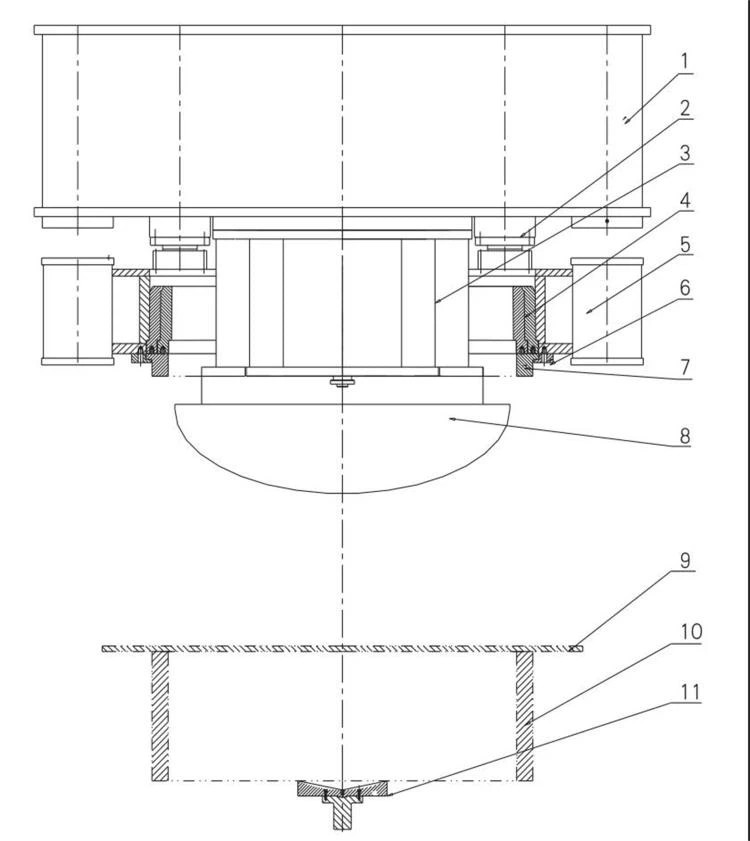

The drawing process of the head drawing hydraulic press is shown in Figure 3. The punch is fixed on the drawing slider, the die ring is installed in the blank holder, the blank holder ring is fixed on the die ring, and the female die is fixed on the moving table On the top, the ejector rotating device is fixed in the lower beam.

Image 3 Diagram of drawing process of head drawing hydraulic press

1-1-stretching slider 2-blank cylinder 3-upper die quick change device and barrel 4-die ring 5-blank slider 6-blank ring mounting flange 7-blank ring 8-punch 9- Workpiece 10 - Die 11 - Ejector Rotary Device

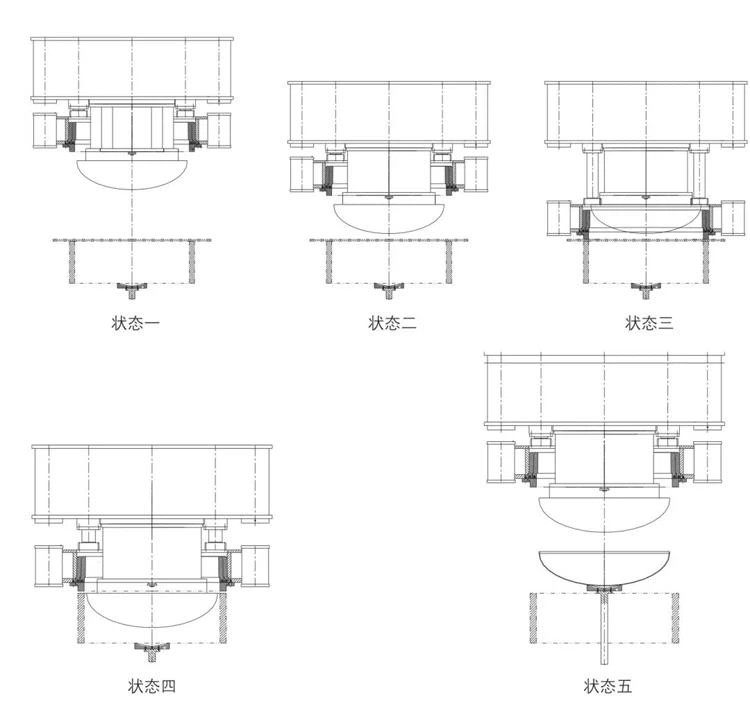

Image 4 Head stretching hydraulic press stretching flow chart

For the head production line currently designed by our company, the opening height of the main machine, the stroke of the slider, the working table, the tensile blank holder force, etc. can be determined according to the needs of users and the needs of the pressing process.

Hot Tags: seal head forming production line, China seal head forming production line suppliers, manufacturers, factory,